Numerous manufacturers and suppliers in the automotive industry are engaged in an exciting race to determine the future of battery technology. One of the most interesting developments that will be ready for series production before 2030 is the solid-state battery. The subtle difference to current battery technology is the use of solid electrolytes. The electrolyte is the medium for transporting ions between the anode and cathode, which in turn causes the electrons to move in the opposite direction. A key advantage is that the solid electrolyte does not burn as quickly as a liquid electrolyte. Manufacturers expect further competitive advantages.

Research is currently focused on optimizing the individual components in the Battery technology. The focus is on the essential components such as the anode material. Graphite is currently used most frequently, but lithium is expected to have more potential in terms of electrochemical processes. The cathode is mostly made from the materials lithium, nickel, manganese and cobalt.

Different approaches to series production

The new combinations of anode, cathode and solid electrolyte alone result in many variations in the development of new batteries. In addition to the greatly reduced risk of fire, the material selection and structure of the solid-state batteries promise a range increase of up to 30 percent compared to conventional lithium-ion batteries. The expected halving of loading times is likely to be even more crucial in practice. This also eliminates the decisive disadvantage compared to the internal combustion engine. The downtime at the charging stations decreases significantly. More cost-effective materials are used for production, which reduces costs. These advantages increase the competitiveness of electromobility and make it interesting for other vehicle classes and segments.

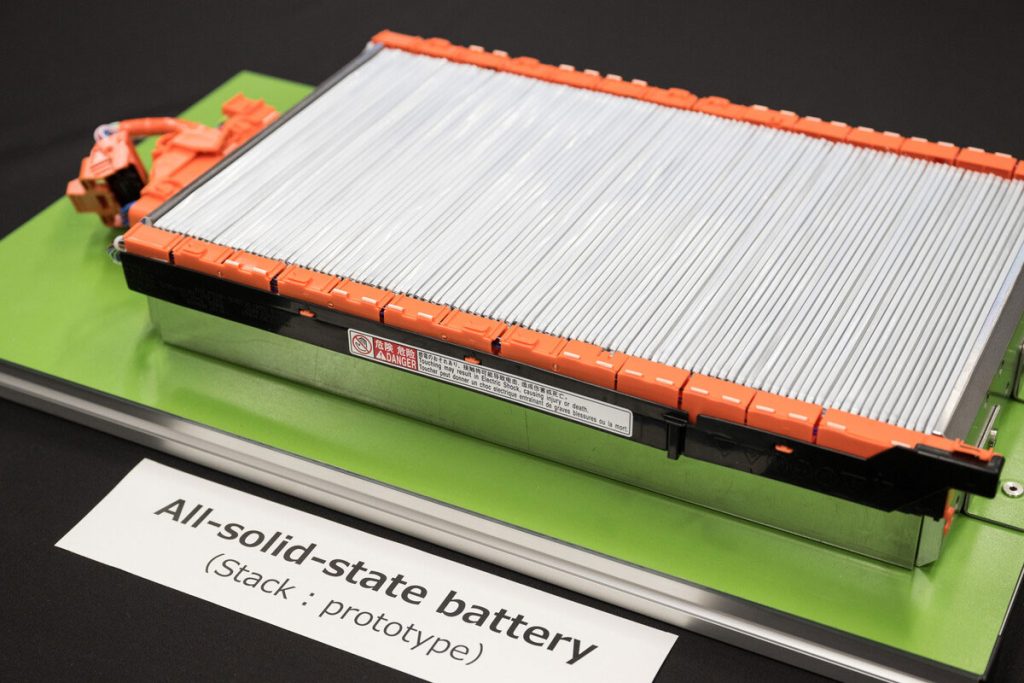

So it's no wonder that all global manufacturers are in a race for pole position. When selecting the electrolyte material Ceramics Sulfur-based is an option, with lithium being favored as an anode. According to its own media report, Toyota's focus is on working with sulfide solid electrolytes, which are considered a promising material for use in solid-state batteries. To this end, Toyota has entered into a cooperation with the Japanese energy company Idemitsu Kosan and is planning to realize its own solid-state battery in three phases.

Present and Future

Toyota's launch includes the development of sulfide solid electrolytes and preparation of a large pilot plant. This will be followed by the start of mass production in a pilot plant. These prototypes will then be used to create a study on mass production. It can probably be expected that it will be ready for series production in the next few years.

Volkswagen is planning to start production in a pilot plant to produce the new batteries as early as 2025. Nissan is conducting intensive research into the new technology and has commissioned a prototype production plant for laminated solid-state batteries in Japan.

| Manufacturers | Development steps | Prognosis |

| Nissan | Prototype of a production system started in 2022 | Series readiness planned for 2028 |

| Volkswagen | The pilot plant is scheduled to start in 2025 | Ready for series production in the following years |

| Toyota | Cooperation with the Japanese energy company Idemitsu Kosan | Ready for series production is forecast from 2027 |

| BMW/Ford | Cooperation with Solid Power | Demo BMW will be presented in 2024 |

| Mercedes / VinFast | Development cooperation with the Taiwanese specialist company Prologium | ProLogium plans to build its first European factory in northern France. Construction of the 48 GWh factory in Dunkirk is scheduled to begin in the second half of 2024 and production will begin at the end of 2026. |

This open race is exciting for the further acceptance of electric cars. The market launch of the solid-state battery is definitely not an immediate end to production for the classic liquid battery. The current lithium-ion batteries are already one step ahead with many years of development and practical use in electric cars. The large production facilities are designed for long-term production periods.

Conclusion

Given the rapid developments, the first cars with solid-state batteries are expected to be introduced as early as 2026. With the faster charging cycles and the expansion of the range, they will put the competition in electric cars, electric trucks and electric buses on a new basis. All global manufacturers have already started developing the new battery technologies.

Addendum

Who is your favorite for the first cars with solid-state batteries?

Cover image – Copyright AddMeshCube – stock.adobe.com

- Outdoor trips with the RAV 4 2,5 l Hybrid 4×4 Adventure - April 30, 2024

- Subaru Solterra – the outdoor BEV - April 30, 2024

- These life hacks make everyday life easier for drivers - April 30, 2024